-

TrainingLearn the intricacies of long-range shooting and maintain your Barrett rifles at an armorer level. Offering long-range shooting courses at locations around the country as well as the Murfreesboro, TN, factory location.

TrainingLearn the intricacies of long-range shooting and maintain your Barrett rifles at an armorer level. Offering long-range shooting courses at locations around the country as well as the Murfreesboro, TN, factory location. -

2025 Firearms CatalogView our digital catalog with the latest offerings from Barrett Firearms.

2025 Firearms CatalogView our digital catalog with the latest offerings from Barrett Firearms. -

Retail Price ListGet up to date retail pricing on Barrett long-range precision rifles and accessories.

Retail Price ListGet up to date retail pricing on Barrett long-range precision rifles and accessories.

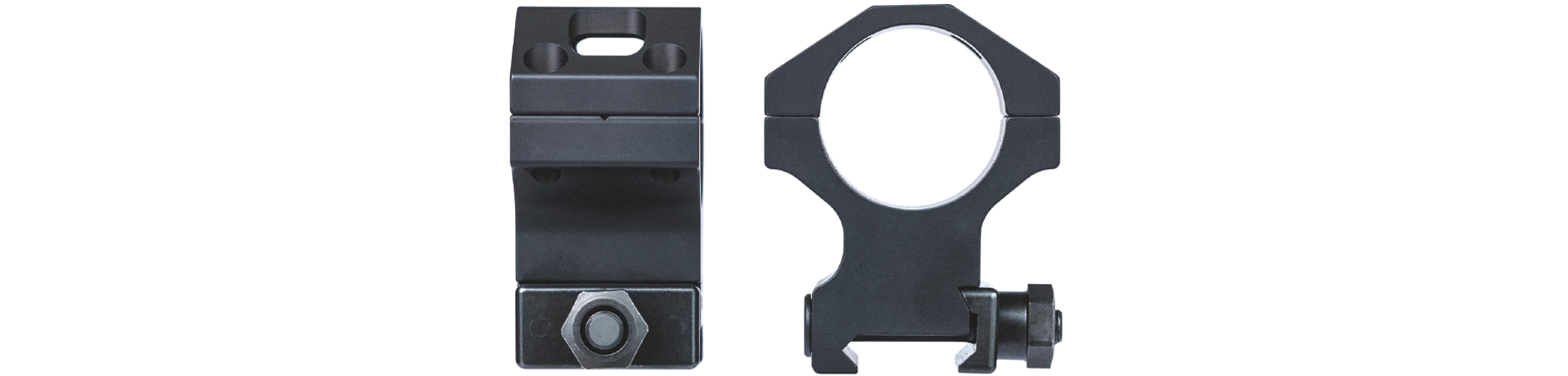

Zero-Gap® Rings

- Weight: 8.32oz (235.9g) (30mm), 8.45oz (239.6g) (34mm)

- Size: 30 mm, 34 mm

- Base Type: Mil-STD 1913 Rail

- Tensile Strength: 83 ksi

- Ring Width: 1.2″ (30.5 mm)

- Surface Gripping Area: 8.192 inch²

- Material: 7075 T-6 Aluminum

- Finish: Hard Anodized Black

- Height (Contact Point to Scope Ring Center): 1.0″-1.7″

For use with 30 mm riflescope tubes on M1913 accessory rails

1.2″ wide clamping area positively grips without damaging scope tube

Aircraft quality 7075 T-6 aluminum

60 HRC (Rockwell C scale) hard-anodized

2.5 times lighter than similar steel rings

Integral 1/4 – 32 steel cross bolt with captured 1/2″ nut

SEAMLESS PROGRESSION

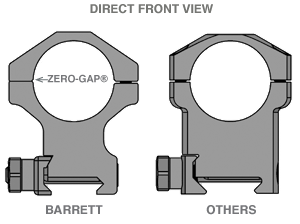

Unlike traditional scope rings which require careful attention be paid to maintaining equal gap between the upper and lower ring halves, Barrett’s ZERO-GAP technology eliminates this tedious process. Simply tighten the cap on the indicated side, verify reticle alignment, tighten the remaining side, and fire away. The end result is a perfect fit between scope and mount that will withstand even the heaviest recoiling rifles. Machined from 7075-T5 aluminum and with MIL-SPEC Type III anodized finish, ZERO-GAP Rings are available in a variety of heights for both 30mm, 34mm, and 35mm optics. Simplicity at its finest.

MATERIALS AND MASS

When selecting a mounting solution for your optics, strength and weight are two important considerations. The greater the overall weight of your complete optics system, the greater inertia (the tendency of a body to resist acceleration) it will have. When a gun is fired it, recoils with instant acceleration. A heavy optics system mounted above the bore axis will resist the sudden rearward movement. A lightweight, strong mount is the best way to combat unwanted sight movement during recoil.

Barrett ZERO-GAP Rings are constructed of high strength 7075 T-6 aluminum. This material is ideal for the application due to its impressive strength; even more impressive strength-to-weight ratio when compared to heavier steels.

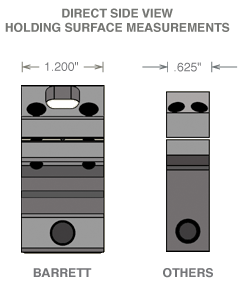

HOLDING AREA

Barrett ZERO-GAP Rings are wider than typical rings at 1.2 inches. This creates a greater surface area of contact between the ring and scope maintube. The benefit is a secure grip on the optic that will hold up under heavy recoil. Along with this solid connection comes protection for your expensive scope. The broad clamping area spreads out the forces and reduces the likelihood of denting or distorting the scope tube. The same benefits in scope holding translate directly to the mount’s ability to hold on the rail. More width in rail clamping area is better.

HEAVY DUTY HARDWARE

The rail clamping cross bolt and nut are precision machined from hardened steel alloys. The cross bolt is securely pressed into the scope ring base, and the end of the bolt is staked to retain the nut. The cross bolt is designed with a broad shoulder to perfectly interface with cross slots of mil spec 1913 rail to resist even the harshest recoil. The top cap of each ring is retained by four robust Torx screws placed with broad spacing to provide consistent and evenly distributed clamping force.

PRECISION AND TOLERANCE

All critical features on Barrett ZERO-GAP Rings are machined with great care. The 30-mm bore will be exactly that with a diameter tolerance of plus or minus .001″, perfect roundness and position in relation to the mounting rail. Angles and surfaces in the rail clamping feature of the lower ring are held to great positional tolerances to ensure the scope is held centered when bolted up to the rail.

FIT AND FINISH

Every component of Barrett ZERO-GAP Rings is carefully handled all the way to packaging. All edges are beautifully rounded to prevent snags and resist corner wear. The 7075 T-6 components are hard anodize coated in black to mil spec MIL-A-8625 Type III Class 2 specification for superior surface hardness (60 Rockwell) and resistance to wear. Steel components are manganese phosphate coated to mil spec DOD-P-16232 Type M Class 2 specification.

ZERO®-GAP DESIGN

The unique scope clamping design of Barrett ZERO-GAP Rings takes care of some old optics mounting challenges. In the past, great attention was required when securing scope ring caps to maintain an equal gap between the lower ring and top cap on each side. There was also the possibility of rotating the scope out of perfect vertical reticle alignment while torquing the cap screws in a side-to-side pattern. These problems are eliminated with the ZERO-GAP design. Simply secure the cap on the indicated side until there is no gap between lower ring and cap, check for perfect reticle alignment, and then torque the remaining side to the required specification.

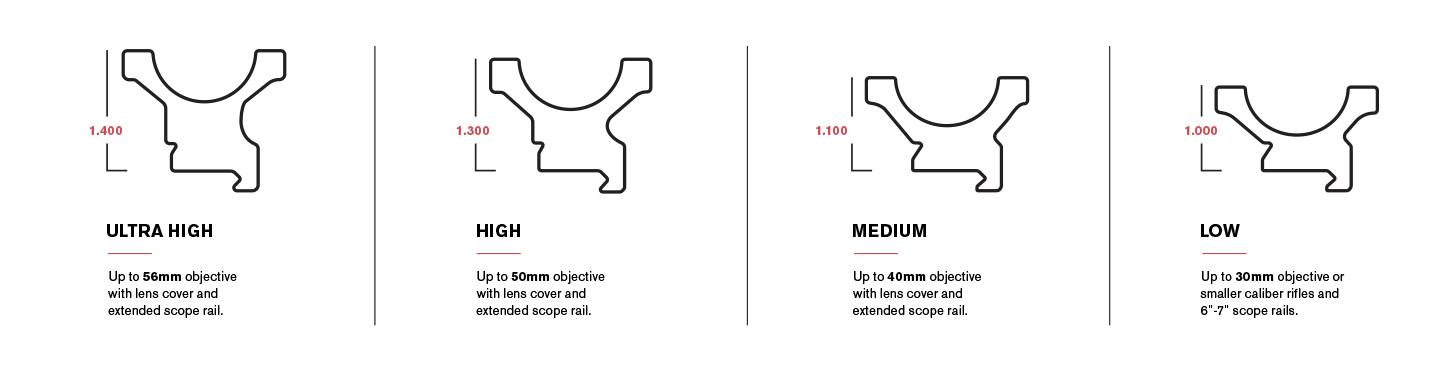

FOR EVERY APPLICATION

Barrett ZERO-GAP® rings are available in four different heights. From a low-mounted action-hugging scope on a hunting rifle to a high-mounted large objective optic on a tactical rifle, you are sure to find one for your particular application.